Product Quality Assurance Using Computer Vision

Introduction

Modern technologies are being integrated into manufacturing processes as a result of the constant search for product quality. A subset of artificial intelligence called computer vision is one such revolutionary force that is changing the landscape of product quality assurance (PQA).

It is becoming more and more important to comprehend the fundamentals of applying computer vision as enterprises move towards automated quality control. With the goal of offering a useful manual for companies looking to improve their quality assurance procedures, this blog provides a succinct analysis of the mutually beneficial link between computer vision and PQA.

Table of Contents

- Product Quality Assurance

- Role of Computer Vision in Product Inspection

- Brief Steps Involved in Product Quality Assurance System

- Monitoring and Continuous Improvement

- Applications and Real-world Impact

- Challenges and Considerations

- Future Trends in Computer Vision for Product Inspection

- Conclusion

- Frequently Asked Questions

1.Product Quality Assurance

Product Quality Assurance (PQA) is a comprehensive set of systematic activities and processes designed to ensure that products meet or exceed predefined quality standards throughout their entire lifecycle.

It encompasses measures taken to prevent, detect, and correct defects or dev variations in a product, ensuring that it adheres to specified requirements and customer expectations.

The goal of Product Quality Assurance is to establish and maintain processes that consistently produce high-quality products, fostering customer satisfaction, and building a reputation for reliability and excellence.

PQA involves various stages, from design and manufacturing to distribution and post-sales support, with a focus on continuous improvement to enhance overall product quality.

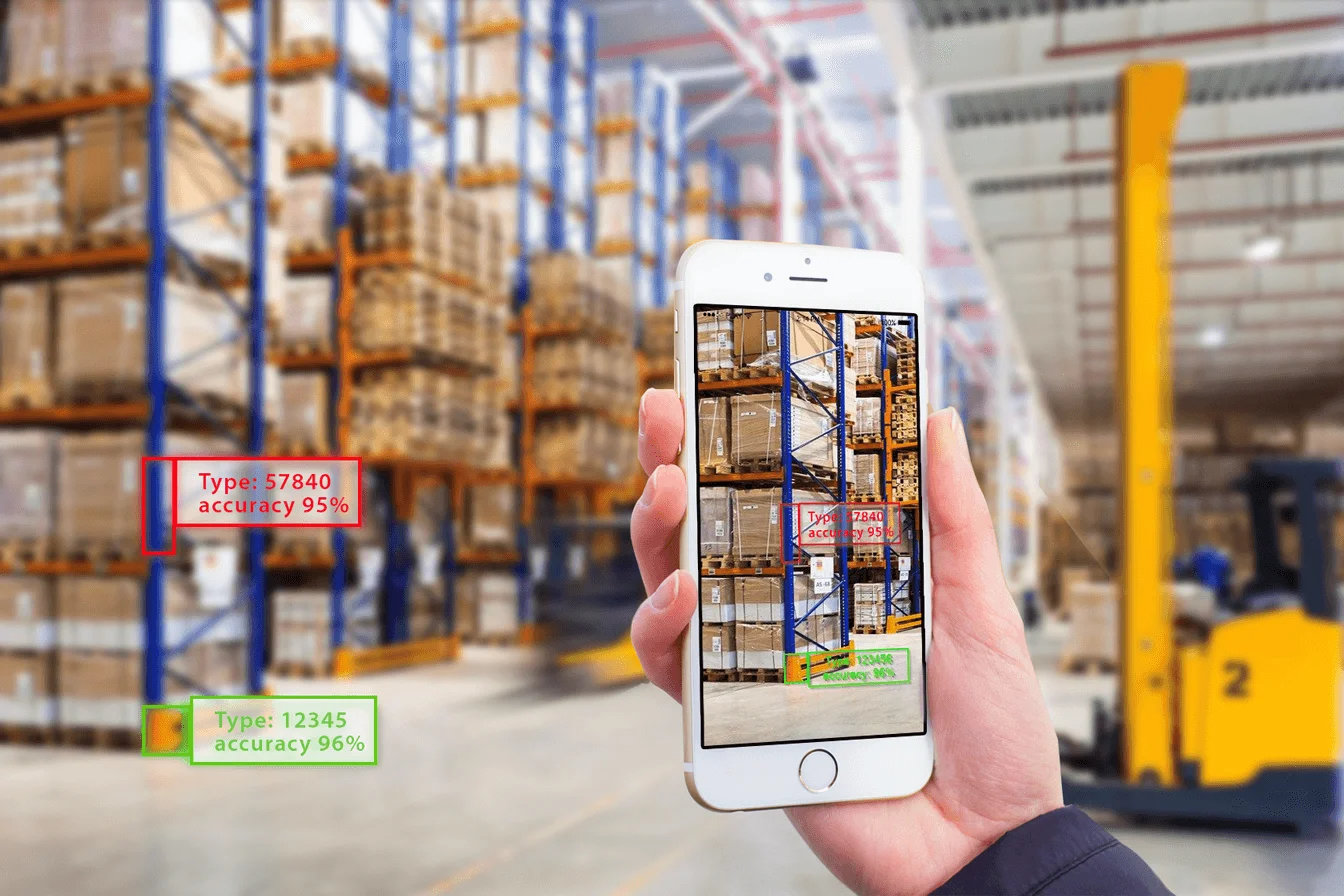

2. Role of Computer Vision in Product Inspection

Computer vision has revolutionized the field of manufacturing and quality assurance through its use in product inspection. A branch of artificial intelligence called computer vision has become a potent instrument for improving and automating inspection procedures so that goods fulfill exacting quality requirements.

Here, we explore the essential elements that characterize computer vision's vital role in product inspection.

1. Precision and Accuracy : Computer vision systems excel in precision and accuracy, surpassing human capabilities in detecting subtle defects or variations in products. This heightened accuracy ensures that even the smallest deviations from quality standards are identified, contributing to the overall improvement of product quality.

2. Speed and Efficiency : Automated product inspection powered by computer vision operates at remarkable speeds, surpassing the pace of manual inspections. This speed is essential for high-volume production lines, where quick and efficient inspections are imperative without compromising accuracy.

3. Consistency in Inspections : Computer vision systems provide a consistent and unbiased approach to inspections. Unlike human inspectors, they do not experience fatigue or variations in attention, leading to a more reliable and uniform assessment of products across different batches.

4. Multi-faceted Inspections : Computer vision can be programmed to inspect products for various characteristics simultaneously. Whether it's detecting defects, checking dimensions, or verifying labels, computer vision systems can perform multi-faceted inspections with versatility, contributing to comprehensive quality control.

5. Adaptability to Varied Products : One of the remarkable features of computer vision is its adaptability to diverse products and manufacturing processes. The same system can be trained to inspect different types of products, making it a flexible solution for industries with varying production lines.

6. Reduction of Human Error : Automated inspections with computer vision significantly reduce the chances of human error. By eliminating the subjective elements of manual inspections, computer vision ensures a more objective and reliable assessment of product quality.

7. Real-time Monitoring : Computer vision allows for real-time monitoring of the production line, enabling instant identification and rectification of defects. This real-time feedback loop contributes to minimizing production downtime and potential losses.

8. Data-driven Decision Making : The data generated by computer vision inspections can be leveraged for data-driven decision-making. Analytics derived from inspection results provide valuable insights into production trends, defect patterns, and areas for continuous improvement.

9. Cost Reduction and Resource Optimization : Automated inspections contribute to cost reduction by minimizing the need for extensive manual labor. The deployment of automated systems reduces labor costs, and the efficiency gains lead to optimized resource utilization, making production processes more economically viable.

3. Brief Steps Involved in Product Quality Assurance System

To effectively integrate computer vision into PQA, a series of key steps must be followed. Data collection and preprocessing lay the groundwork, ensuring a reliable dataset for model training.

Subsequent stages involve data annotation, model selection, and training, where algorithms learn to recognize defects and components. Augmentation techniques enhance model robustness, and validation and testing phases validate its performance on diverse data sets.

3.1 Data Collection and Preprocessing:

The foundation of any successful computer vision system lies in the quality and diversity of the data it is trained on. The initial step involves collecting a comprehensive dataset representative of the production environment. Preprocessing techniques are then applied to clean and enhance the data, ensuring that the model is trained on reliable information.

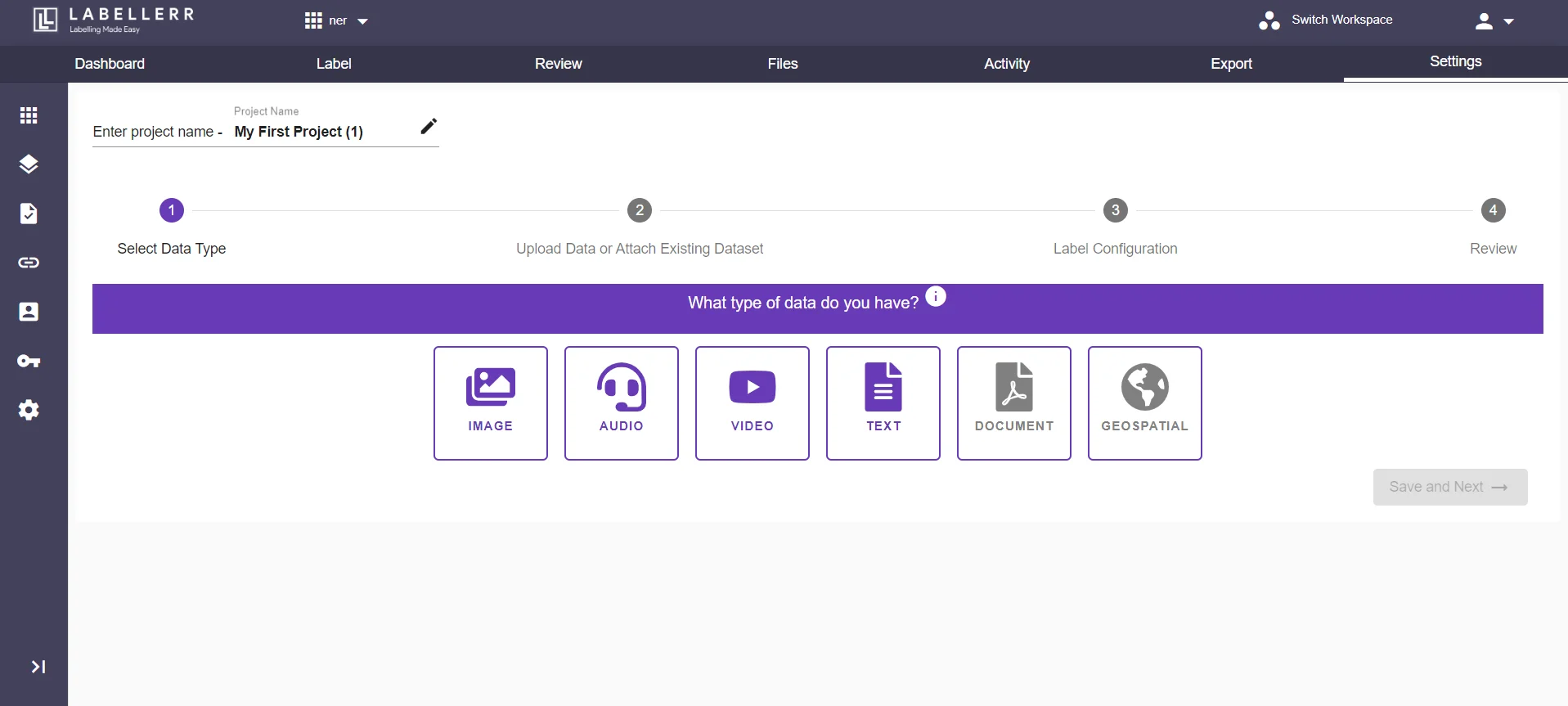

3.2 Data Annotation:

To train a computer vision model for PQA, a labeled dataset is essential. This involves annotating images with bounding boxes or segmentation masks, indicating the location and extent of defects or components. Tools like Labellerr facilitate this process, ensuring accurate annotations for effective model training.

3.3 Model Selection and Architecture:

Choosing the right model architecture is crucial for the success of a PQA system. Models like Convolutional Neural Networks (CNNs) have proven effective in image recognition tasks. The selection of the architecture depends on the specific requirements of the quality assurance task.

3.4 Model Training:

The annotated dataset is used to train the chosen model. During this phase, the model learns to recognize patterns and features that distinguish between acceptable and defective products. The training process involves adjusting the model's parameters to minimize errors and enhance accuracy.

3.5 Augmentation Techniques:

To enhance the model's robustness, data augmentation techniques are applied. This involves artificially expanding the dataset by introducing variations such as rotation, flipping, or changes in lighting conditions. Augmentation ensures that the model generalizes well to different scenarios.

3.6 Validation and Testing:

Once the model is trained, it undergoes validation and testing phases. Validation helps fine-tune parameters and prevent overfitting, while testing evaluates the model's performance on new, unseen data. Rigorous testing is crucial to ensure the reliability of the PQA system.

3.7 Integration and Deployment:

After successful testing, the model is integrated into the production line for real-time inspection. Seamless integration ensures minimal disruption to the manufacturing process. Deployment involves adapting the model to the production environment, accounting for variations in lighting and product positioning.

3.8 Real-time Processing and Optimization:

For effective PQA, real-time processing is essential. The computer vision system continuously analyzes incoming data, making instant decisions on product quality. Optimization techniques are employed to enhance the system's speed and efficiency.

4. Monitoring and Continuous Improvement:

The implementation of a PQA system doesn't end with deployment. Continuous monitoring is necessary to identify any issues or drift in performance. Regular updates and retraining of the model with new data contribute to continuous improvement, ensuring the system adapts to changes in the production environment.

Monitoring and continuous improvement constitute integral components of an effective Product Quality Assurance (PQA) system. Monitoring involves the systematic observation and evaluation of the quality assurance processes and their outcomes.

This ongoing scrutiny ensures that the established standards are consistently met and deviations are promptly identified. Continuous improvement, on the other hand, is a proactive approach aimed at enhancing the effectiveness of quality assurance processes over time.

By analyzing performance metrics, feedback, and data from ongoing operations, organizations can identify areas for refinement, implement corrective actions, and optimize their PQA systems. This iterative cycle of monitoring and improvement is essential to adapt to evolving production dynamics and uphold or elevate product quality standards.

5. Applications and Real-world Impact

Computer vision has emerged as a transformative force in enhancing quality assurance across diverse industries. The applications of computer vision in quality assurance are far-reaching, revolutionizing traditional inspection processes and offering real-world impacts that significantly elevate overall product quality.

Here, we explore the specific applications and the tangible effects of implementing computer vision in quality assurance.

1. Automated Defect Detection : Computer vision excels in detecting defects with unparalleled precision. From manufacturing lines to product assembly, automated systems equipped with computer vision algorithms can swiftly identify and classify defects, ensuring that only products meeting stringent quality standards proceed further in the production process.

2. Product Classification and Sorting : Computer vision enables the automated classification of products based on predefined criteria. This is particularly valuable in industries where products have varying specifications. Automated sorting based on visual characteristics ensures that each product is directed to the appropriate category, optimizing the overall production workflow.

3. Dimensional Accuracy Checks : Quality assurance often involves ensuring products meet specific dimensional criteria. Computer vision systems are adept at performing accurate dimensional checks, verifying product dimensions against predefined standards. This ensures that products conform to precise specifications, minimizing variations in size and shape.

4. Label and Packaging Verification : Computer vision is employed for verifying labels, barcodes, and packaging integrity. Automated inspections ensure that the correct labels are applied, barcodes are readable, and packaging is intact. This not only guarantees compliance with regulatory requirements but also enhances overall product presentation.

5. Real-time Process Monitoring : Computer vision systems provide real-time monitoring of production processes. This instantaneous feedback allows for immediate corrective actions in case of deviations or defects, preventing the production of substandard products and minimizing potential waste.

6. Quality Control in Food and Pharmaceuticals : In industries such as food and pharmaceuticals, where product safety is paramount, computer vision ensures stringent quality control. Automated inspections identify contaminants, irregularities, or deviations from quality standards, contributing to the delivery of safe and high-quality products to consumers.

7. Improving Manufacturing Efficiency : By automating quality assurance processes, computer vision enhances manufacturing efficiency. The speed and accuracy of automated inspections contribute to streamlined production workflows, reducing the time required for manual inspections and increasing overall throughput.

8. Supply Chain Traceability : Computer vision aids in supply chain traceability by capturing and analyzing visual data throughout the production and distribution processes. This not only enhances transparency but also facilitates tracking and identifying the source of any quality issues that may arise.

6. Challenges and Considerations

The integration of computer vision into product inspection, while promising transformative benefits, comes with its set of challenges and considerations. Understanding and addressing these factors is crucial for successful implementation.

Here, we explore the key challenges and considerations associated with leveraging computer vision for product inspection.

1. Complexity of Product Variations : Products within a manufacturing line often exhibit diverse shapes, sizes, and features. The complexity of handling these variations poses a challenge for computer vision systems, necessitating robust algorithms capable of adapting to diverse product characteristics.

2. Ambient Conditions and Lighting : The quality of visual data captured by computer vision systems is highly dependent on ambient conditions and lighting. Variations in lighting conditions across different shifts or production environments can impact the accuracy of inspections, requiring adaptive algorithms and sophisticated image processing techniques.

3. Data Quality and Annotation : The quality of the dataset used for training computer vision models is paramount. Insufficient or inaccurately annotated data can lead to sub-optimal model performance. Ensuring a high-quality, diverse dataset is crucial for the successful deployment of computer vision in product inspection.

4. Integration with Existing Systems : Integrating computer vision into existing production systems can be a complex process. Compatibility issues, the need for additional hardware, and potential disruptions to ongoing operations should be carefully considered during the integration phase.

5. Scalability and Performance : As production volumes scale, the performance of computer vision systems must keep pace. Ensuring that the system remains efficient and responsive, even under increased workloads, is a consideration to prevent bottlenecks in the production line.

6. Ethical and Regulatory Compliance : Adhering to ethical standards and regulatory compliance is imperative when implementing computer vision in product inspection. Ensuring the responsible use of technology, addressing privacy concerns, and complying with industry-specific regulations are essential considerations.

7. Human-AI Collaboration : While computer vision automates many aspects of product inspection, there is a need for effective collaboration between automated systems and human inspectors. Establishing clear protocols for human-AI collaboration ensures that the strengths of both are leveraged to achieve optimal inspection outcomes.

7. Future Trends in Computer Vision for Product Inspection

Looking ahead, several trends are poised to shape the future landscape of computer vision for product inspection, further enhancing its capabilities and applicability.

1. Advancements in Deep Learning Architectures : Ongoing developments in deep learning architectures, including novel neural network structures and algorithms, will continue to enhance the ability of computer vision systems to learn and adapt to complex inspection tasks.

2. Edge Computing for Real-time Processing : The adoption of edge computing enables computer vision systems to process data closer to the source, facilitating real-time inspections without the need for extensive data transfer. This trend contributes to increased speed and efficiency in product inspection.

3. Explainable AI for Enhanced Transparency : As the importance of transparency in AI systems grows, the integration of explainable AI techniques allows for clearer understanding of how computer vision models arrive at specific inspection decisions, addressing concerns related to the "black box" nature of some deep learning models.

4. Multi-modal Sensing Integration : Combining visual data with data from other sensor modalities, such as infrared or hyperspectral imaging, enhances the richness of information available for inspections. Multi-modal sensing integration provides a more comprehensive view of product characteristics.

5. Continuous Learning and Adaptability : Future computer vision systems for product inspection will likely incorporate continuous learning capabilities, allowing them to adapt to evolving production environments and variations in product specifications over time.

6. AI-driven Automated Annotation : Addressing the challenge of data annotation, the future may see the rise of AI-driven tools that automate the annotation process, reducing the manual effort required to prepare high-quality datasets for training.

7. Increased Collaboration Across Industries : Collaboration and knowledge-sharing across industries will become more prevalent, allowing insights and best practices from one sector to benefit others. This cross-industry collaboration accelerates the development and adoption of effective computer vision solutions for product inspection.

Conclusion

Incorporating computer vision into Product Quality Assurance is a transformative step towards achieving higher levels of precision and efficiency in manufacturing. By following the outlined steps and leveraging proven methodologies, businesses can enhance their quality control processes, ultimately delivering superior products to consumers.

The ongoing advancements in computer vision technology promise even greater potential for the future of PQA, making it an integral component in the pursuit of excellence in manufacturing.

Frequently Asked Questions

Q1.What is computer vision in quality management?

AI vision systems accurately carry out quality control inspections by utilizing cutting-edge algorithms and computer vision technologies. By detecting even the smallest flaws or deviations from the norm, these systems make sure that only top-notch goods are produced and shipped from the factory.

Q2.What are 3 areas in industry where computer vision is currently being used?

Businesses in a wide range of industries, including retail, security, healthcare, construction, automotive, manufacturing, logistics, and agriculture, are greatly impacted by computer vision research.

Q3.What is computer vision for quality control in automated manufacturing systems?

Manual inspections take a lot of time, whereas computer vision systems can analyse hundreds of product photos in a second. This maintains constant quality standards while greatly accelerating the production process.

Simplify Your Data Annotation Workflow With Proven Strategies

.png)