Power Grid Inspection using Computer Vision

Manual power grid inspections are risky and slow. Discover how Computer Vision and drones are transforming utility maintenance. This guide explores how AI automates defect detection, ensures worker safety, and enables predictive maintenance to prevent outages before they happen.

The modern power grid is often described as the most complex machine ever built a sprawling network of transmission and distribution (T&D) assets that forms the backbone of our economy.

For utility operators, maintaining the reliability of this infrastructure is a continuous battle against aging components, vegetation encroachment, and increasingly volatile weather patterns.

Traditionally, grid inspection has been a labor-intensive, high-risk endeavor. Utilities have relied heavily on "legacy" methods: sending line crews into hazardous environments or deploying helicopters for visual patrols.

While effective to a degree, these manual workflows are inherently limited. They are capital-intensive, subject to human fatigue and cognitive bias, and restricted by safety regulations that limit how often critical assets can be assessed.

As the energy sector faces pressure to improve grid resilience and operational efficiency, the status quo is no longer sustainable.

This is where Computer Vision (CV) can be used in inspection and monitoring of PowerGrid, and in this blog we will explore how it enhances reliability, efficiency, and safety.

Challenges in Current Method

Despite technological advancements, many inspection processes still rely on methods that are decades old. These traditional approaches face three significant bottlenecks:

High Safety Risks

Manual inspection often requires line workers to climb dangerous high-voltage towers or hang from helicopters to visually check lines.

This "live-line" work is inherently hazardous, exposing highly skilled workers to the risks of electrocution and falls. Even helicopter-based inspections carry significant aviation risks, especially in difficult terrain or poor weather.

Subjectivity and Human Error

When inspections are performed manually whether by a human on the ground with binoculars or an operator reviewing drone footage, the results are subjective. Fatigue, distraction, or lack of experience can lead to missed defects.

A hairline crack in an insulator or a slightly rusted bolt might be overlooked by one inspector but flagged by another, leading to inconsistent data and unreliable risk assessments.

Too Much Data

Utility companies have started using drones to capture images, which is safer, but it creates a new problem: data overload. A single drone flight can generate thousands of high-resolution images.

Reviewing these images manually is slow, expensive, and unscalable. Without automation, the data sits in servers, and critical insights are buried under terabytes of unanalyzed footage.

How Computer Vision Can Solve this?

Computer Vision (CV) acts as the "brain" that processes visual data collected by drones, fixed cameras, or robots. By training AI models on thousands of images of power grid components, utilities can automate the analysis process with superhuman speed and consistency.

Here is how Computer Vision transforms the inspection workflow:

1. Automated Defect Detection

Computer vision models (such as YOLO or Faster R-CNN) can be trained to detect specific anomalies that are invisible or easily missed by the human eye.

- Component Analysis: AI can instantly identify and classify components like insulators, dampers, and bolts.

- Damage Recognition: The system can flag specific defects like corrosion (rust), broken insulator discs, flashed-over surfaces, or loose wires with high precision.

2. Vegetation Management

One of the leading causes of power outages and wildfires is vegetation growing too close to power lines.

- Stereo Vision & LiDAR Fusion: CV algorithms can analyze 3D depth data to measure the exact distance between tree branches and power lines.

- Predictive Growth: By monitoring these distances over time, the system can predict when a tree will breach the safety zone, allowing utilities to trim vegetation proactively rather than reactively.

3. Thermal Anomaly Detection

Visual inspections only tell half the story. Integrating thermal imagery with computer vision allows for the detection of hotspots.

- Overheating Components: A corroded connector or an overloaded transformer will generate excess heat before it fails physically. CV systems can overlay thermal data onto visual feeds to pinpoint these hotspots automatically, preventing fires and blackouts.

4. Predictive Maintenance

Perhaps the biggest shift is moving from "finding faults" to "predicting failures." By continuously analyzing the condition of assets over time, Computer Vision enables Predictive Maintenance. instead of fixing things when they break, utilities can repair components that show early signs of wear (like minor surface rust), extending the lifespan of the grid and saving millions in emergency repair costs.

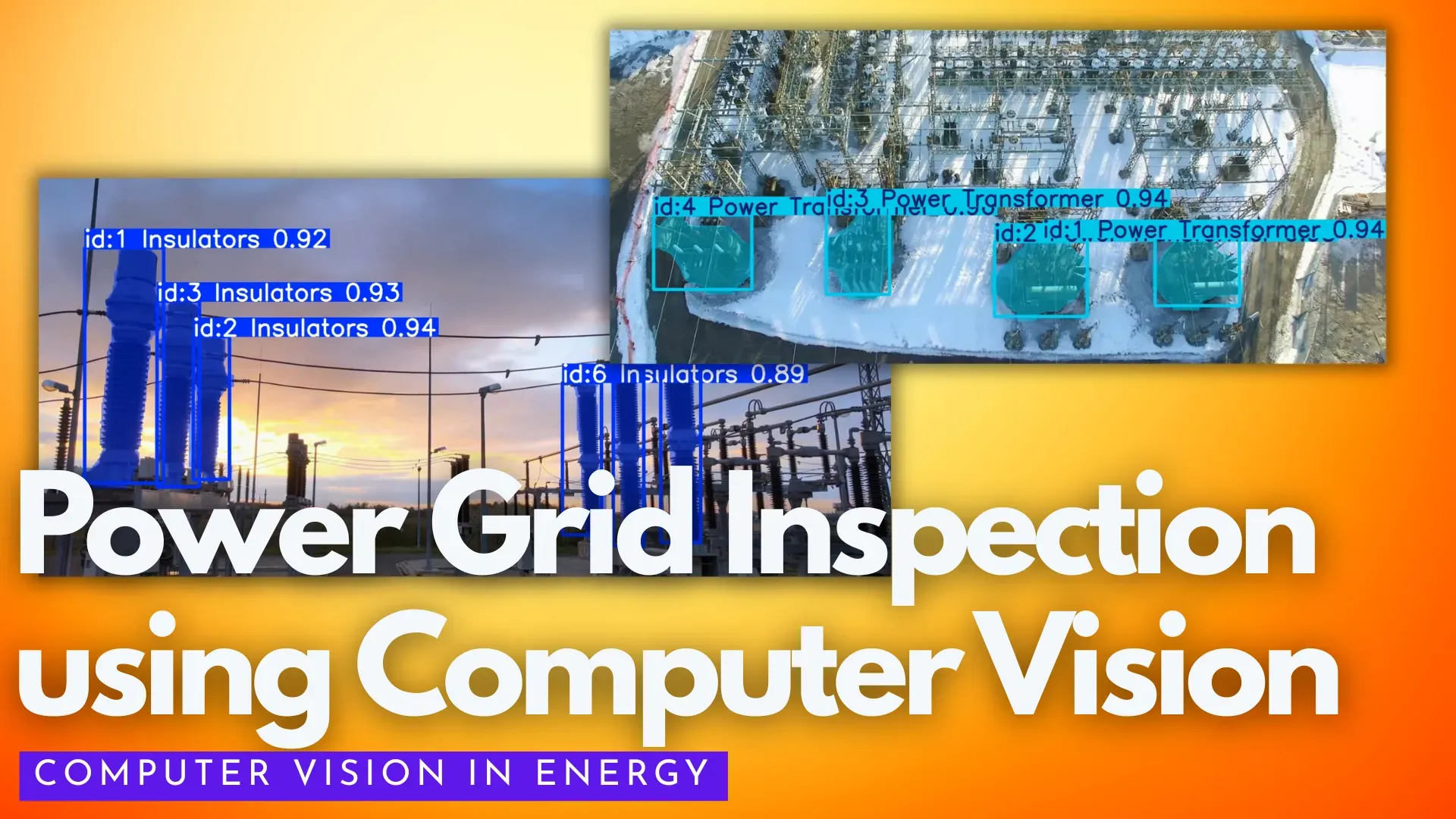

Computer Vision Inference Showcase

Training CV model on drone or inspection video can make this process automated and more effective.

Here are some CV model inference result that show how effective it can be:

Drone View based Monitoring

Ground based View Inspection

Conclusion

Adopting Computer Vision for power grid inspection is more than just a technology upgrade; it is a smarter way to work. By combining drones with AI, utility companies can finally solve the difficult trade-off between speed, safety, and cost.

The impact is clear. First, we drastically improve safety by keeping line workers on the ground and out of harm's way. Second, we turn the massive amount of inspection data into clear, actionable answers, removing the guesswork.

Finally, and most importantly, this technology allows the industry to move from "reacting to outages" to "preventing them entirely."

As our power grid grows larger and more complex, managing it the old-fashioned way simply won't be enough. Computer Vision provides the reliability and efficiency we need, ensuring a safer and more stable energy future for everyone.

FAQs

How does Computer Vision improve power grid inspection safety?

It removes the need for human inspectors to climb dangerous towers or perform risky helicopter flights. Instead, drones capture the data, and AI analyzes it, keeping workers safely on the ground.

What specific defects can AI detect on transmission lines?

AI models can be trained to detect very small details, including rusted bolts, cracked insulators, frayed wires, and overheating components (using thermal data), as well as vegetation growing too close to the lines.

Is Computer Vision better than manual inspection?

Yes, it is generally faster and more consistent. While humans can get tired or miss small details, Computer Vision processes thousands of images with the same high level of accuracy every time, reducing the chance of missed defects.

Simplify Your Data Annotation Workflow With Proven Strategies

.png)